Coring into a post-tensioned (PT) slab is not a “grab a drill and go” task. Post-tensioning tendons—high-strength steel cables in sleeves—are hidden in the concrete, rebar runs in multiple directions, and conduit is often embedded.

If you nick a tendon, you jeopardize the structure and trigger an expensive repair. Hit conduit, and you shut down a system and invite rework. The goal is simple: put the hole exactly where the design needs it without touching anything you shouldn’t. The reality, however, is anything but simple.

Why It’s Tricky

- Tendon paths aren’t straight. PT cables rise and fall through the slab to control deflection, so a spot that looks safe in plan (top-down view) may not be safe at the depth you core.

- Rebar congestion. Steel rebar grids on the top and bottom—plus ties and extra bars at openings—leave very few clear zones.

- Embedded systems. Electrical, data, and sometimes plumbing run inside the slab, and drawings may not reflect last-minute field shifts.

- Non-negotiable locations. MEP cores (mechanical, electrical, plumbing) often must land at precise points to maintain slope, clearance, or equipment alignment, even when steel or conduit is in the way.

How We Do It Right

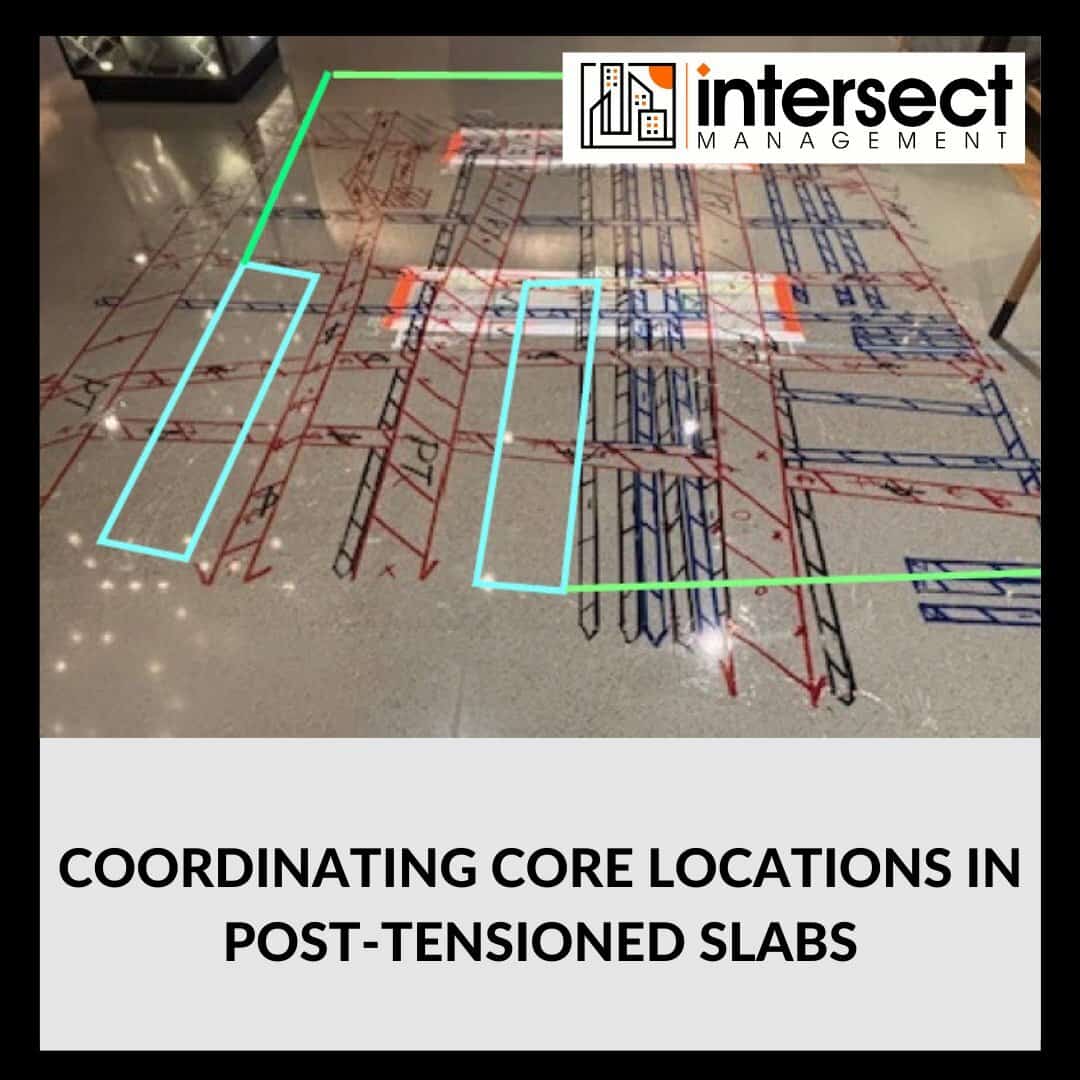

- Advanced 3D modeling. We pull all embedded systems into a coordinated model so proposed cores and no-cut zones are clearly visible.

- Precise field verification. Each core zone is scanned with ground-penetrating radar (GPR) before drilling to verify tendon and conduit locations.

- Real-time problem-solving. When a scan reveals a conflict, we shift to a preapproved backup location or obtain a designer-approved resolution—never guesswork.

- Multi-disciplinary execution. Structural sets the clearances, electrical confirms conduit, and the field team controls access, coring, and documentation.

Credit Where It’s Due

Special recognition goes to DPR Construction and CSI Electric for their outstanding effort in navigating this complex coordination challenge. Their collaborative approach and technical expertise in managing the intricate relationship between structural post-tensioning systems, reinforcement steel, and electrical infrastructure demonstrate the highest level of construction coordination.

Ensuring the Coordination Level Projects Demand

At Intersect Management, we specialize in bringing this level of coordination to every project we manage. Our role is to connect the dots between disciplines, technologies, and field execution—ensuring that tasks like coring post-tensioned slabs are performed safely, accurately, and in full alignment with design intent.

Through proactive modeling, communication, and verification, we make certain that critical activities are executed the right way the first time—protecting both the structure and the schedule.

– By Charles Suh